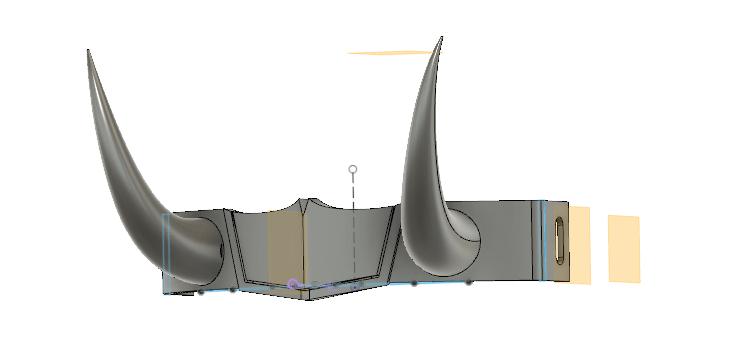

When I made this I was just learning how to CAD so this mask is based on an STL file from Thingiverse.

The first time I printed it, the mask was too small and I thought the sides of the mask felt a bit narrow so even correctly sized the mask wouldn’t fit comfortably. Unfortunately because all I had was an STL file to work with, I was unable to change the angle of the sides. I decided it might be possible to use a heatgun to bend the sides out once the mask was scaled properly. To ensure that this modification was possible and to avoid printing and wasting a mask, I used a heat gun on this first version to make sure I could expand the sides to fit around my face. I heated up the print slowly because I was worried that I would either melt or break the print but eventually the plastic moved enough that I knew I could modify the angle of the sides to match my own face.

I printed a new copy of the design that was correctly sized this time. When it finished a day later I was very nervous to try and heat bend it because I didn’t want to needlessly waste another day-long print. I heated the prints with the heat gun slowly again, heating up a section from front to back before slowly pushing it out. Finally, after an hour of careful but slow heat gunning, I had a mask that fit. (There are no straps which is a poor design choice on my part trying to be ‘accurate’ so when worn it has to be glued to my face).

When researching how to finalize a 3D print for a previous project, I came across the Bondo method which worked last time, but this mask had a lot of fine lines that I did not want to accidentally fill in. I learned more about sanding 3D prints and I decided to go for that route. I sanded in circles with various grits for a few hours until it felt smooth. It was a long and tiring process but I could finally paint it which is my favorite part. It was simple to paint, just black and grey. I first sprayed it all black since I wanted the inside painted and not 3D print blue. Then when it dried I painted the dark and light grey shades with acrylic paint and for the final step to complete it I finished it with a glossy clear coat to seal it.

I love how it turned out and it felt so good to finally see the final product. I was particularly proud when my brother asked me where I bought it and I was able to tell him that this was the part I had printed on his printers.